Controlling flight paths

At SABCA we design, manufacture or maintain actuators for commercial aviation and defence industry. Actuation systems are the joints, muscles and nerves of an airplane. They are the components that set other parts in motion. In the Flight Control System, Actuators move flight control surfaces like the ailerons, elevators, rudder, flaps and spoilers according to Roll/Pitch/Yaw inputs from the Pilots or Autopilot System. Actuators can also be found in most other systems such as Landing Gear System, Brake System, Door Operating Systems and more.

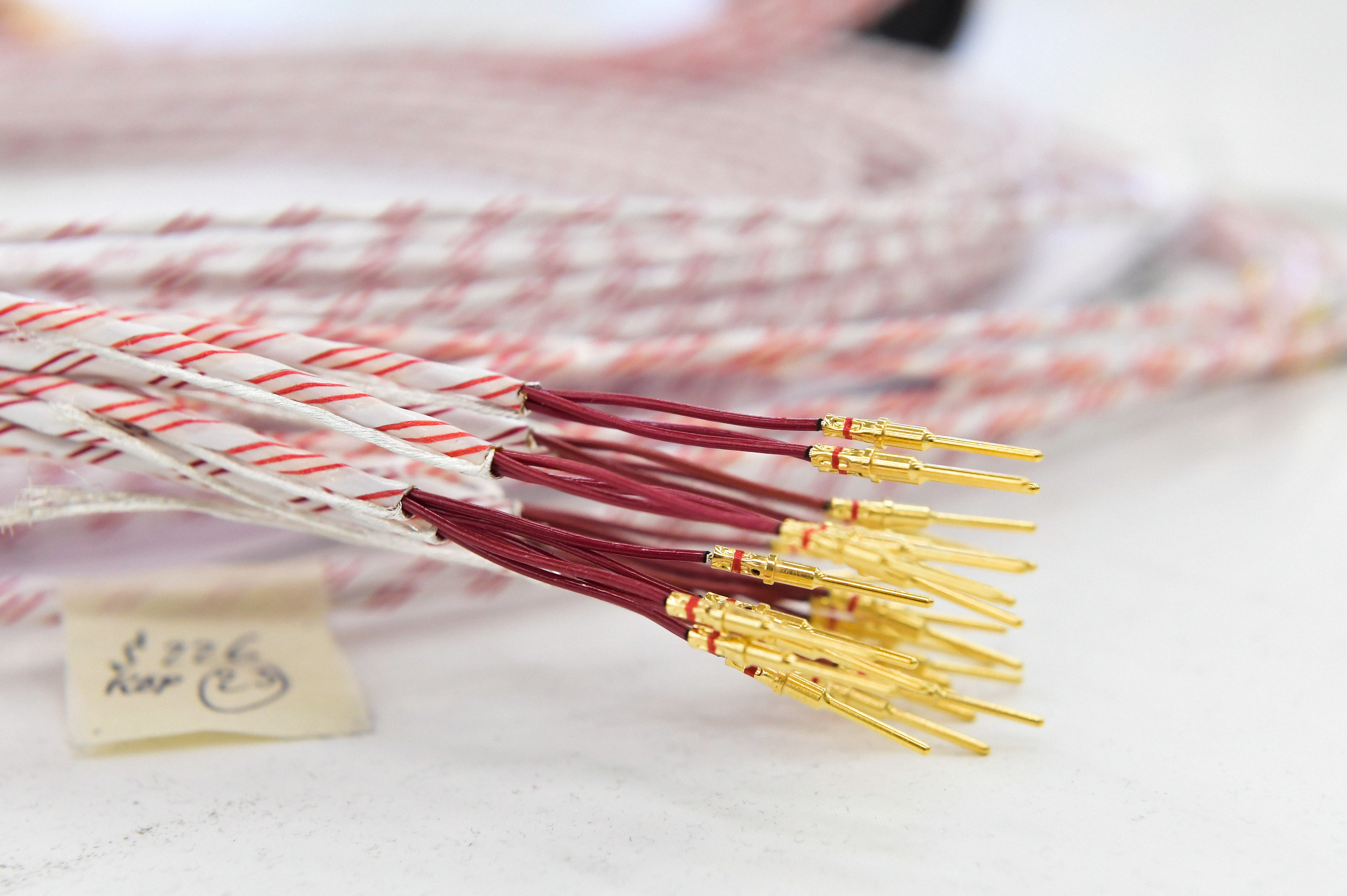

SABCA produces electrohydraulic and electromechanical actuators and is, in light of further electrification of future aircrafts, developing lighter and less energy consuming electric actuators. A new technology to improve performance and increase reliability.

Aircrafts and jets

interactive_images__airplane__flight_control

interactive_images__airplane__utility_actuators

interactive_images__airplane__ancillary_systems

Products for aviation

Electrification

For decades already, the aerospace sector has been moving towards greater electrification. Actuation systems are naturally following the same trend. Electromechanical technologies and its applications will continue to grow in overall aircraft content.

Read more

Actuation systems

SABCA has many years of experience in design, manufacturing, and maintenance of flight control actuators for business jets and commercial aircrafts. This includes hydraulic and electromechanical systems, as well as hybrid electro-hydraulic technologies.

Read more

Ancillary systems

Besides its tier 1 activities, SABCA also positions itself as a tier 2 supplier for specific work packages. Our added value lies in complex electromechanical and hydraulic systems, for which our interdisciplinary design and manufacturing expertise can makes the difference.

Direct Drive Valve capacity

Delivered

Flight hours (million)

Production (per year)

MTBF (hours)